Vissi Blank

VISI Blank is an integrated solution for the development of 2D blank shapes from complex 3D models. It is particularly useful in the generation of blank forms for the sheet metal, progressive die, press tooling and crash tooling industries. VISI Blank bene ts from seamless integration with the acclaimed VISI Modelling software, using the industry standard Parasolid kernel combined with Vero’s proprietary surface modelling and 2D design technology.

FAQs

-

The simple user interface ensures that it is quick and easy to create blank forms from complex geometry, understand the results in a graphical interpretation and help establish the optimum manufacturing process. A comprehensive material database ensures that the analysis can be performed on virtually any material.

-

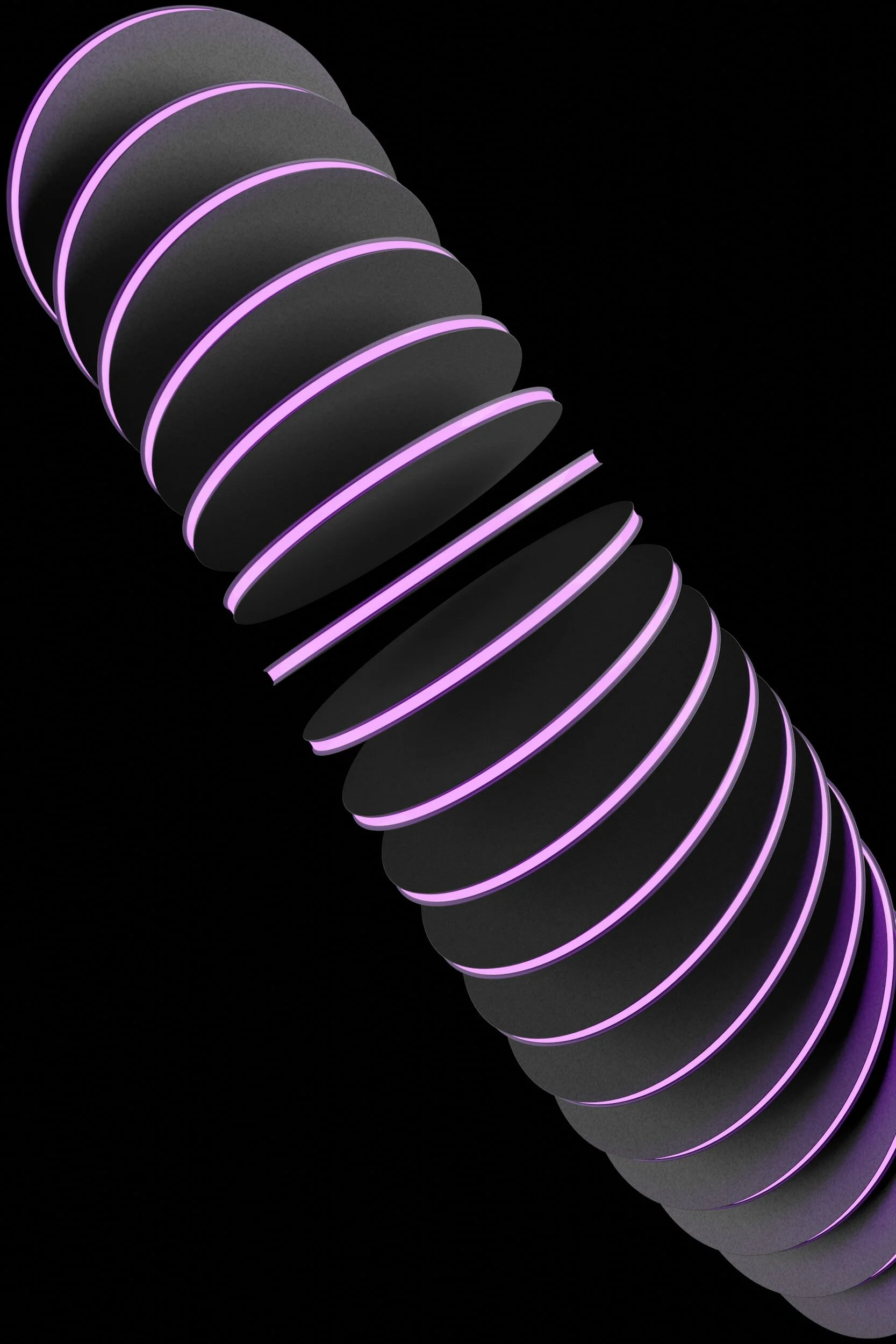

Results are provided in a clear and concise graphical display which can be further output to a report sheet format. Graphical analysis includes colour coded representation of material areas suspect to 'thinning' and "wrinkling" allowing accurate identification of potential problem areas prior to physical die design. Using the graphical scale the software will identify where the material is within tolerance and any areas that may exceed this.

-

Virtually any 3D form can be flattened into a developed blank to ensure that the optimum amount of stock material is used for production thus reducing supplementary manufacturing or finishing operations. Generally the form can be produced within a few minutes and has a proven accuracy of being within 1% of the finished component. The manual or traditional CAD approach to this would typically involve many hours of calculation and much less accuracy.

Features

Visi Blank is an integrated solution for the development of 2D blank profiles from complex 3D models.

Benefits from seamless integration with Visi Progress.

Ability to show areas of thinning and wrinkling.